Sasta pays attention to the issues of service support of the supplied equipment. The company has established a Service Center.

Service center’s tasks:

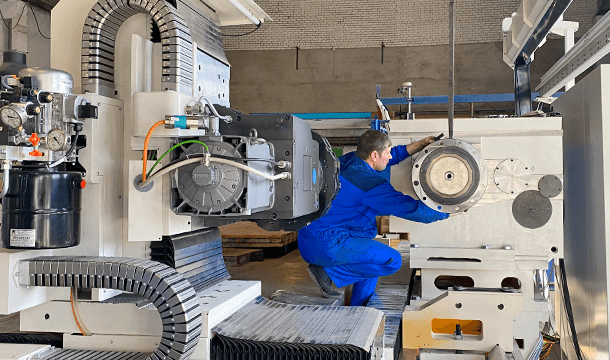

• start-up and adjustment works;

• maintenance service of equipment (medium or small repairs, technical inspection) during the warranty and post-warranty period of the machines;

• training of customer’s specialists in operation and maintenance of the machines;

• overhaul and modernization of universal equipment and CNC machines.

Start-up work and adjustment works

Start-up and adjustment works on the delivered equipment are performed by the specialists of Sastaaccording to the signed contract provisions.

List of works during commissioning:

• inspection of machine installation and leveling;

• commissioning works in accordance with the standard program and test procedure of the machine or in accordance with the agreed technological process for the customer’s parts machining;

• commissioning of the machine.

Service

Engineers of Sasta go to the place of the equipment operation, diagnose problems, make a defective sheet and a list of necessary spare parts. After delivery of all components we carry out repair of the equipment and we provide a warranty for the performed works.

Repair cost and terms are established after drawing up of the defects sheet and the specifi cation statement for average repair by the customer.

Warranty service

Warranty service of the machines manufactured by Sasta is carried out within 12 months, in accordancewith the supply contract terms.

After-sales support

Sasta recommends to make an agreement on the after-sales maintenance of metal-working equipment, which can be concluded for a period of 1 to 3 years or more.

Training

The specialists of Sasta are ready to train the technical personnel of the customer within the frames of the mutually agreed program at Sasta factory or upon the reduced program at the customer’s site.