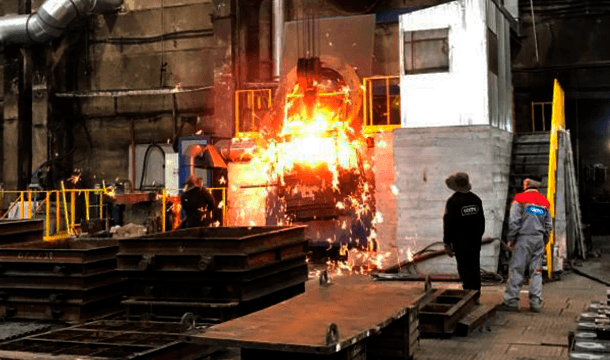

Sasovo foundry factory – this is a modern high-tech foundry that was created to provide the machine building complex and other industries with high quality molded castings from various grades of steel and cast iron.

The main advantage of our foundry production is its technological flexibility and the ability to manufacture various types of castings using a single technology and in a single stream, which allows to perform high quality orders both in small volumes and in small batches and to produce serial products.

The foundry was opened in 2003.

Planned capacity is 250 000 kg of iron casting per month.

Castings producibility by weight from 10 kg to 6200 kg.

-

• Induction melting units INDUCTOTHERM;

• IMF forming equipment using high-speed third generation mixers and mechanical regeneration of the molding mixture;

• automated line of moldless molding.

CASTING MATERAL:

- Cast iron with lamellar graphite: (engineering castings for general use) graphite cast iron 10, graphite cast iron 15, graphite cast iron 20, graphite cast iron 25, graphite cast iron 30, graphite cast iron 35 (GOST 1412-85)

- High-strength cast iron with nodular graphite: cast iron 50, cast iron 60, cast iron 70, cast iron 80 (GOST 7293-85)

- Bearing cast iron:(for castings used in friction units) cast iron -1, cast iron -2 (GOST 1585-85)

- High-silicon cast-iron: cast iron -15 (GOST 2233-85)

- High-alloy cast iron: cast iron 16 (GOST 7769-82)

- Carbon and low-alloy steels: (casting machine parts) steel10L, steel 15L, steel 20L, steel 25L, steel 30L, steel 40L, steel 45L, steel 50L, steel 60L (GOST 977-88).

- steel 20Х, steel 30Х, steel 35Х, steel 40Х, steel 45Х, steel 50Х (GOST 4543-71) etc.

Research and development department

Factory laboratory

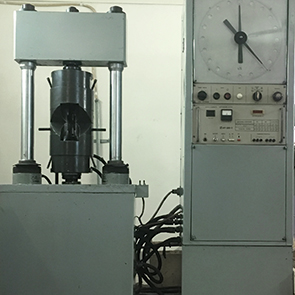

At the Sasovo Foundry there is a factory laboratory, the main tasks of which are:

• Quality control of molding mixtures;

• Control of the temperature and chemical composition of the melt;

• Control of microstructure and mechanical properties of castings;

• Metrological control.

Includes the following departments:

• Spectral laboratory– determination of the chemical composition of various types of cast iron and steels;

• Mechanical laboratory – static and dynamic tests for resistance, tensile, hardness;

• Metallography laboratory – research of microstructure of cast iron and steel;

• Land laboratory– incoming inspection, samples and measurements of bulk materials;

• Chemical laboratory – chemical analysis of various types of cast iron and steels.

Qualified specialists carry out casting control at all stages of the production process, including verifying and metrological supervision.

AMONG THE KEY CUSTOMERS OF THE SASOVO FOUNDRY FACTORY THERE ARE MACHINE-BUILDING AND MACHINE-BUILDING ENTERPRISES OF RUSSIA AND CIS COUNTRIES:

OJSC «Sasta»

(lathe, vertical lathe and pipe cutting machines)

OJSC «Gomelskii zavod stanochnih uzlov»

(lathe, turning lathe equipment)

LLC « Vladimirsky machine building factory «Technika»

(lathe, milling, grinding machines, special purpose equipment)

LLC «Srednevolzskii stankostroitelnii zavod»

(lathe machines)

LLC «DVT»

(universal metal cutting machines)

АО «STP-Lipezkoe stankostroitelnoe predpriatie»

(grinding, drilling, lathe and milling machines)

OJSC «Astrakhanskii stankostroitelnii zavod»

(metalcutting press-forging equipment, abrasive equipment, woodworking equipment)

LLC Scientific and production innovation company «SPLAV»

(development and improvement of the design of ferrosilicate subsurface and deep earthing)

OJSC «Stankostroitel»

(special purpose equipment)

CJSC «Bezema»

(special purpose vehicles)

OJSC «ZVI»

(common industrial asynchronous electric motors)

LLC «KOM»

(mechanical transmissions)

LLC «ZMT»

(mechanical transmissions)

LLC «Ruselprom-Resource»

(electrical machines and drivers)

OJSC «Litmashpribor»

(foundry production)

CJSC «Ruven»

(ventilation and draft equipment)