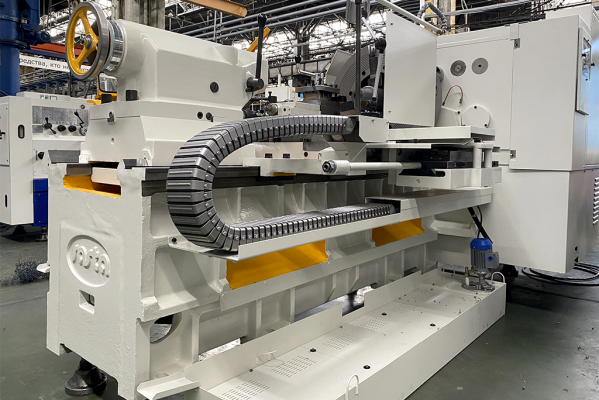

CA983

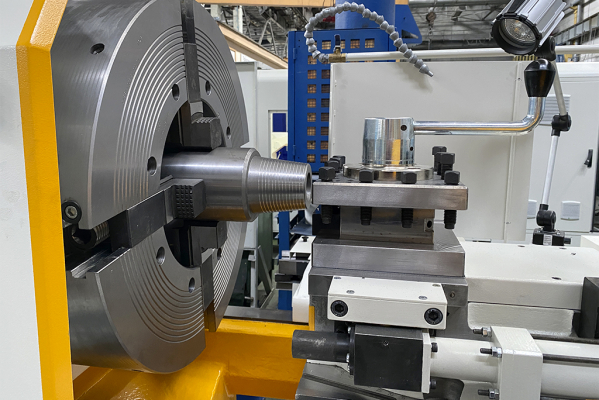

Easy-to-use pipe-threading lathe designed for processing of long pipes and parts of pipe connections with a diameter of up to 340 mm, used for the production and transportation of oil and natural gas.

Main features

| Spindle bore diameter |

340 mm |

| Max. diameter of the workpiece to be processed over bed | 830 mm |

|

Max. diameter of the workpiece to be processed over carriage |

450 mm |

Description of construction

- Easy-to-use pipe-threading lathe designed for processing of long pipes and parts of pipe connections with a diameter of up to 340 mm, used for the production and transportation of oil and natural gas.

- It is also suitable for all types of turning works.

- Suitable for cutting metric and inch (including conical) threads.

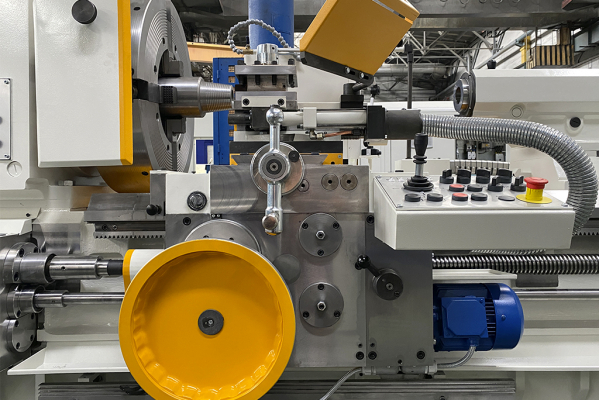

- It is equipped with a hydraulic mechanism for automation of one thread-cutting passage (hydro-rebound) when threading in manual mode and in a cycle.

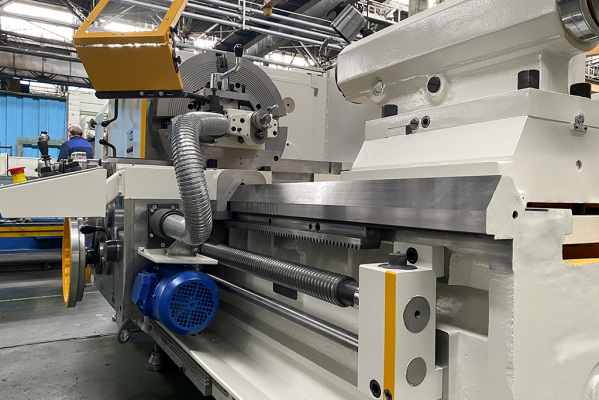

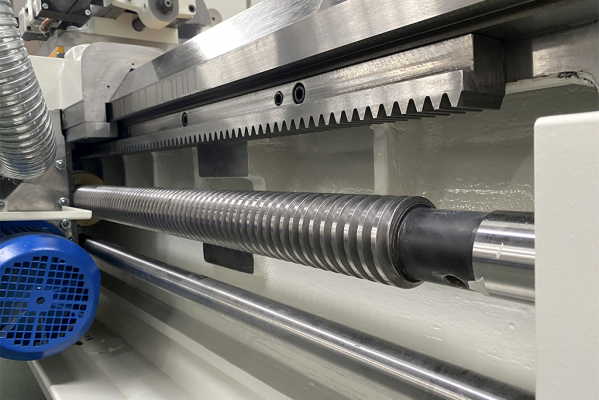

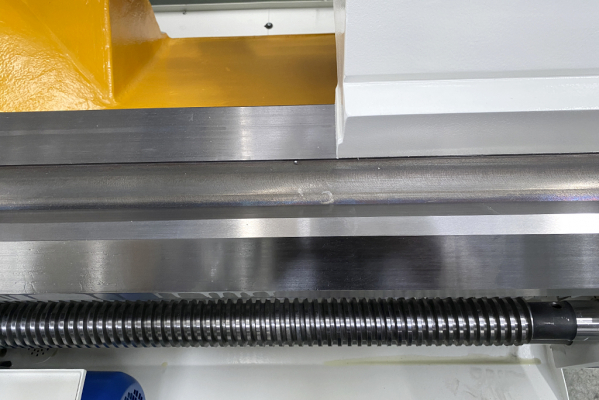

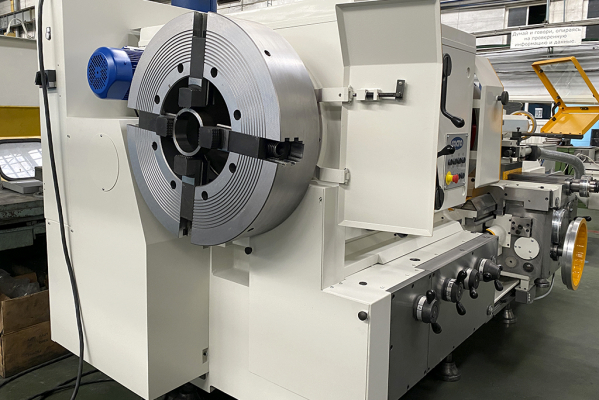

- The machine is assembled on a cast iron bed, with hardened sliding guideways.

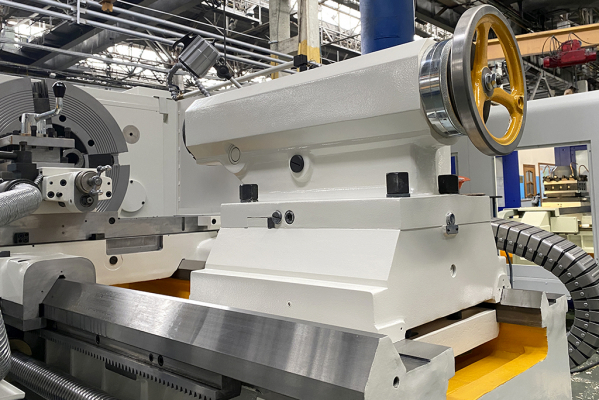

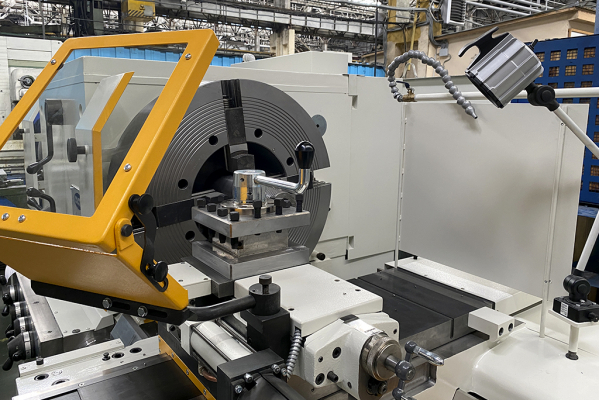

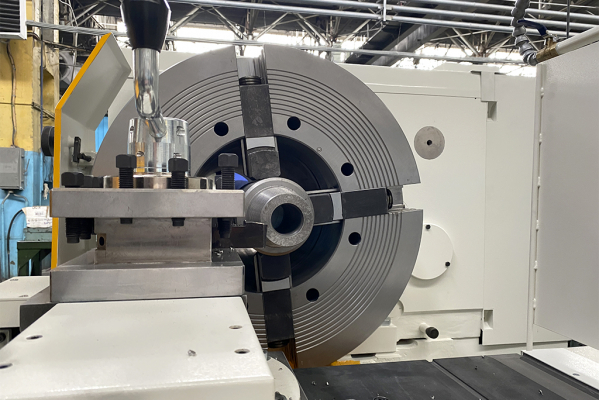

- The machine is equipped with two mechanized 4- jaws chucks with a diameter of 720 mm.

Specifications

| CUTTING AREA | ||

| Spindle bore diameter | 340 | mm |

| Max. diameter of the workpiece to be processed over bed | 830 | mm |

| Max. diameter of the workpiece to be processed over carriage | 450 | mm |

| Max. length of the workpiece to be processed in centres |

1000 2000 3000 |

mm mm mm |

| Max. length of the workpiece to be processed with taper attachment | 500 | mm |

|

Max. weight of the installed workpiece in chuck in centers |

2000 5000 |

kg |

| SPINDLE | ||

|

Spindle speed |

8-355 | rpm |

| Speed adjustment |

stepped (12 steps) |

|

| Main motor power | 15 | kW |

| Max. torque | 3000 | Nm |

| Chuck diameter | 720 | mm |

| TRAVEL | ||

| X axis travel | 500 | mm |

| Z axis travel |

1000 2000 3000 |

mm mm mm |

| RAPID FEED | ||

| X axis rapid feed | 2200 | mm/min |

| Z axis rapid feed | 5300 | mm/min |

| FEED | ||

| Cutting feed range | 0,042-1,179 | mm/min |

| Cut thread range | 0,09-2,67 | mm/rev |

| CUT THREADS STROKE LIMITS | ||

| Metric | 1-28 | mm |

| Inch | 28-1 | threads per inch |

| TURRET | ||

| Number of tools | 4 | |

| Tool section | 32x32 | mm |

| Rotary mechanizm | manual | |

| TAILSTOCK | ||

| Quill travel | 240 | mm |

| Quill diameter | 120 | mm |

| Quill taper | MT6 | |

| DIMENSIONS AND WEIGHT | ||

| Length |

3640 4640 5640 |

mm mm mm |

| Width | 2050 | mm |

| Height | 1675 | mm |

| Weight |

10300 10900 11500 |

kg kg kg |

Completion of the machine

Standard equipment:

- 4-position tool holder with hydro-rebound

- Flap on the carriage with inspection glass

- Taper attachment

- Tailstock with dead and live centers MT6

- Self-centering 4-jaw chucks with independet movement of jaws and electromechanical clamping

- Chucks guard with locking

- Coolant tank

- Work light

- Leveling pads

Request

Ask a Question