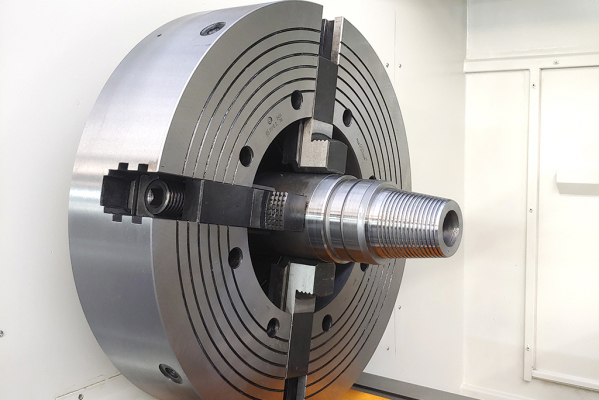

CNC version. The largest torque (up to 7625 Nm) on the spindle in its class. Designed for processing long pipes and parts of pipe connections with a diameter of up to 340 mm, used for the production and transportation of oil and natural gas.

СА983F3

Main features

|

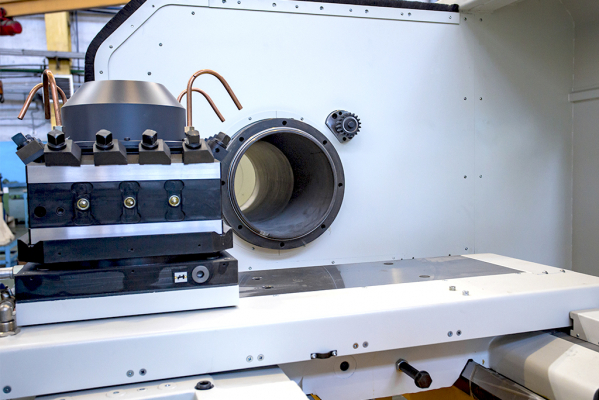

Spindle bore diameter |

340 mm |

|

Max. diameter of the workpiece to be installed over bed |

830 mm |

| Max. diameter of the workpiece to be processed over carriage |

410 mm |

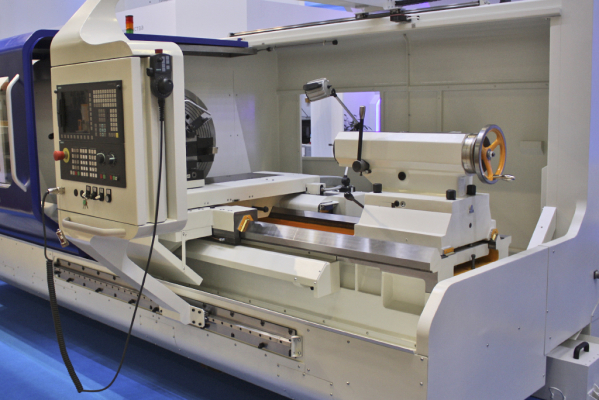

Description of construction

- CNC version.

- Designed for processing in automatic and semi-automatic cycle of long pipes and parts of pipe connections with a diameter of up to 340 mm, used for the production and transportation of oil and natural gas.

- The largest torque (up to 7625 Nm) on the spindle in its class.

- It is also suitable for all types of turning works.

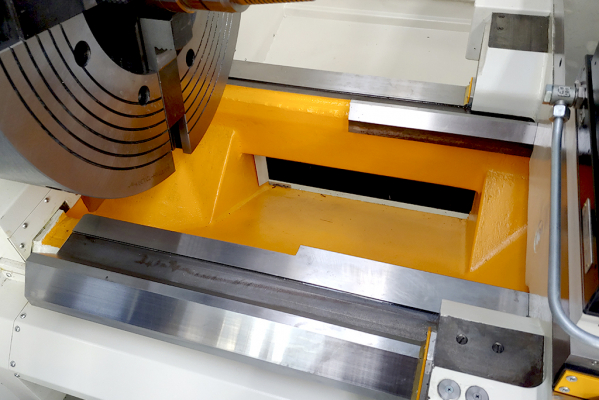

- The machine is assembled on a cast iron bed, with hardened sliding guideways.

Specifications

| CUTTING AREA | ||

| Spindle bore diameter | 340 | mm |

| Max. diameter of the workpiece to be installed over bed | 830 | mm |

| Max. diameter of the workpiece to be processed over carriage | 410 | mm |

| Max. length of the workpiece to be processed in centres |

1050 2050 3050 |

mm mm mm |

|

Max. weight of the installed workpiece in chuck in centers |

2000 5000 |

kg |

| SPINDLE | ||

|

Spindle speed limits |

5-750 | rpm |

| Speed adjustment |

stepped, at 2 ranges |

|

| Main motor power |

22/26,4- Siemens 30/37,5- Fanuc |

kW |

| Max. torque |

4200/5250- Siemens 4982/6228- Fanuc |

Nm |

| FEED |

|

|

| Х/Z cutting feed range | 1-4000 | mm/min |

| Cut thread range | 0,5-150 | mm/rev |

| Х/Z rapid feed | 6000 | mm/min |

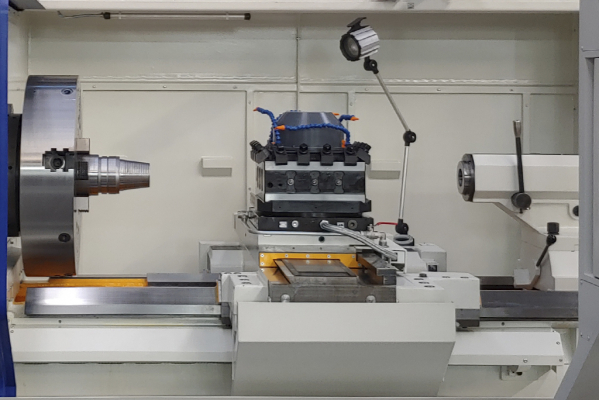

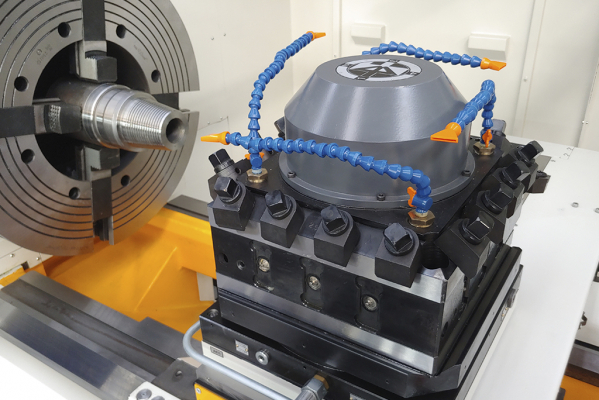

| TURRET | ||

| Number of tools | 4 (12) | |

| Tool section |

32x32 (40x40) |

mm mm |

| Rotary mechanizm | manual | |

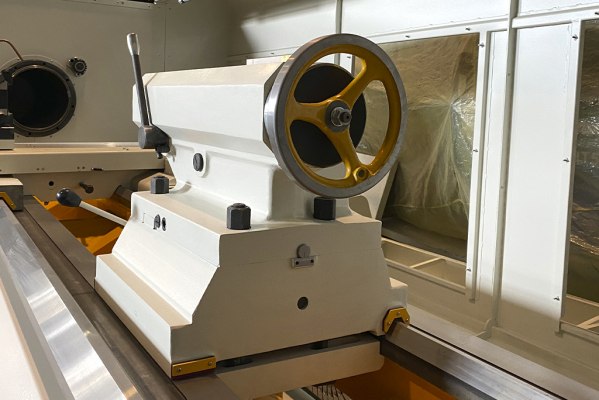

| TAILSTOCK | ||

| Quill travel | 240 | mm |

| Quill diameter | 120 | mm |

| Quill taper | MT6 | |

| DIMENSIONS AND WEIGHT | ||

| Length |

5170 6170 7170 |

mm mm mm |

|

Width without panel swivel with panel swivel |

3050 3780 |

mm mm |

| Height | 2000 | mm |

| Weight |

10000 11000 12000 |

kg kg kg |

Completion of the machine

Standard equipment:

- CNC Fanuc 0i-TF

- Control panel with touch screen

- MPG portable

- Self-centering 4-jaw chucks with independet movement of jaws and electromechanical clamping

- 4-position precise positioning cutter head (with Hirth coupling)

- Tailctock with dead and live centers MT6

- Coolant system

- Chip tray

- Semi-cover protection for cutting area

- Work light

- Leveling pads

Request

Ask a Question