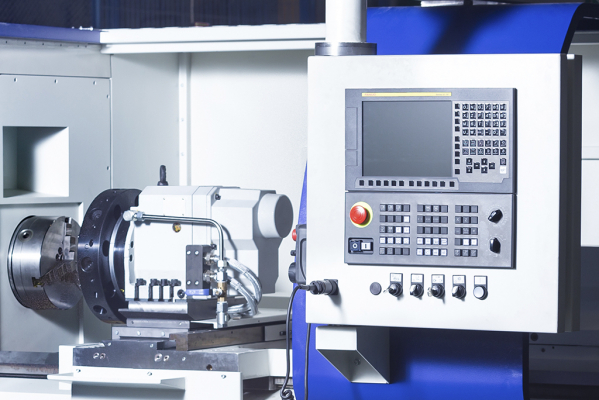

СА500 FLEX

The machine is balanced by characteristics with a very strong construction. The ability to upgrade an cycle control system to a full Fanuc CNC system without additional installation work, only by entering a service code.

Main features

|

Spindle bore diameter |

55 mm |

|

Max. diameter of work piece to be installed over bed |

500 mm |

|

Max. diameter of work piece to be installed over carriage |

250 mm |

Description of construction

-

The machine is balanced by characteristics with a very strong construction.

-

Rigid contsruction: rigid solid-cast bed, wide v-guides, five precision radial-axial bearings in the spindle unit,

feeds servo-drives and ball screws instead of mechanical kinematic relations, – all this ensures accuracy and

reliability of the machine.

-

The ability to upgrade an cycle control system to a full Fanuc CNC system without additional installation work, only by entering a service code.

-

Handles for work as the universal machine.

Specifications

| CUTTING AREA | ||

| Max. diameter of the workpiece to be installed over bed | 500 | mm |

|

Max diameter of the workpiece to be processed over bed over carriage |

350 (500) 250 |

mm |

| Length of the workpiece installed in the centers | 1000 | mm |

| Length of the workpiece processed in the centers | 880 | mm |

|

Max. weight of the workpiece installed in chuck in centers |

300 2000 |

kg kg |

| SPINDLE | ||

| Spindle speed | 20 - 3500 | rpm |

| Speed adjustment |

stepless, at 2 ranges |

|

| Main motor power | 15/18,5 | kW |

| Max. torque | 797/997 | Nm |

|

Chuck diameter

|

250 (315, 400) |

mm |

| Spindle nose according to DIN55026 | A6 | |

| Spindle bore | 55 |

mm |

| RAPID FEED | ||

| X rapid feed | 5000 | mm/min |

| Z rapid feed | 10000 | mm/min |

| FEED | ||

|

X cutting feed range |

1-2000 | mm/min |

|

Z cutting feed range |

1-4000 | mm/min |

| Cut thread stroke limit, | 0,5-150 | rpm |

| Feed speed adjustment | stepless |

|

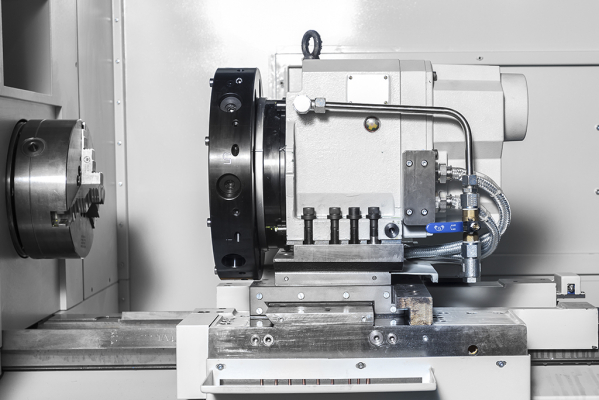

| TOOLHOLDER | ||

| Number of tools | 4 (8) | |

| Tool section | 25х25 | mm |

| Tool change |

manual (automatic) |

|

| TAILSTOCK |

|

|

|

Quill travel |

200 |

mm |

| Quill diameter | 100 |

mm |

| Quill taper | MT5 |

|

| DIMENSIONS AND WEIGHT |

|

|

| Length |

3290 |

mm |

| Width | 1845 |

mm |

| Height | 1915 |

mm |

| Weight | 2200 | kg |

Completion of the machine

Standard equipment:

- Fanuc cycle CNC control system

- Handles for work as the universal machine

- Control panel with touchscreen

- 3-jaws manual self centering chuck

- 4-position toolholder of exact positioning (with hirth coupling), 25х25 mm

- Chuck guard with lock

- Toolholder protective cover with watch window

- 8-position turret VDI40

- Work light

- Tailstock on inflatable bag with dead center and live centers

- Coolant system

- Chip tray

- Toolkit for machine installation

Request

Ask a Question