CNC machines are designed for turning in the chuck and centers of parts with straight, step and curved profile. The range of spindle speed control allows processing of products made of both and non-ferrous metals and alloy steels.

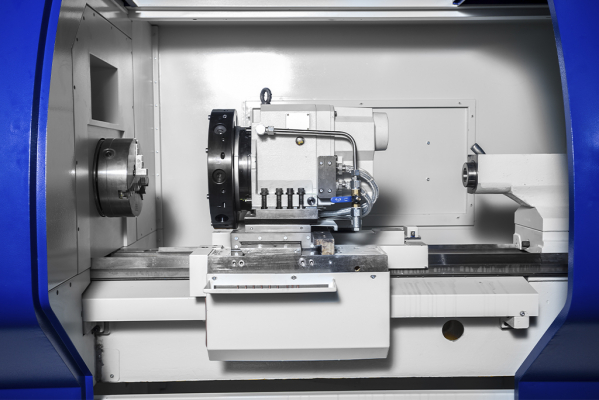

СА600F3/F4

Main features

| Spindle bore diameter | 102 mm |

|

Max. diameter of the workpiece to be installed over bed |

560 mm |

|

Max. diameter of the workpiece to be processed over carriage |

320 mm |

Description of construction

- Rigid solid-cast bed artificially aged for stress relieving provides long-term stability of the machine accuracy.

- Wide v-guides hardened at depth 1.5-2 mm to 52 HRC and grinded ensure long life.

- Surfaces of moving units (carriage, tailstock) are scrapped and covered by special antifriction coating to provide movement with min. runout and friction-free.

- 3 axis 2 ranges headstock with stepless adjustment provides high torque (up to 2200 Nm) with increased accuracy.

- Linear scales at all the axes (option).

Specifications

| CUTTING AREA | ||

|

Max. diameter of the workpiece to be installed over bed |

560 | mm |

|

Max. diameter of the workpiece to be processed over carriage |

320 | mm |

|

Distance between centers |

1000 1500 2000 3000 |

mm mm mm mm |

|

Max. weight of the workpiece |

1500 | kg |

| SPINDLE | ||

|

Spindle speed |

2800 | rpm |

|

Speed adjustment |

stepless, at 2 ranges |

|

| Main motor power |

15/18,5 - Fanuc 12/15 - Siemens |

kW |

|

Max. torque |

783/978 - Fanuc 943/1178 - Siemens |

Nm |

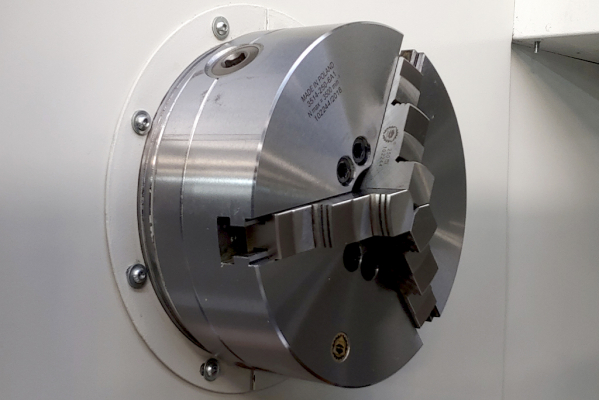

| Chuck diameter |

315 (400, 500) |

mm mm |

| Spindle nose according to DIN55026 | A11 | |

| Spindle bore | 102 | mm |

| RAPID FEED | ||

| Carriage cross travel | 265 | mm |

| X rapid feed | 5000 |

mm/min |

| Z rapid feed |

10000 (6000 for DBC=3000 mm) |

mm/min |

| FEED | ||

| X cutting feed range | 1-4000 |

mm/min |

|

Z cutting feed range |

1-4000 | mm/min |

| Cut thread stroke limit, | 0,1-160 | rpm |

| Feed speed adjustment | stepless |

|

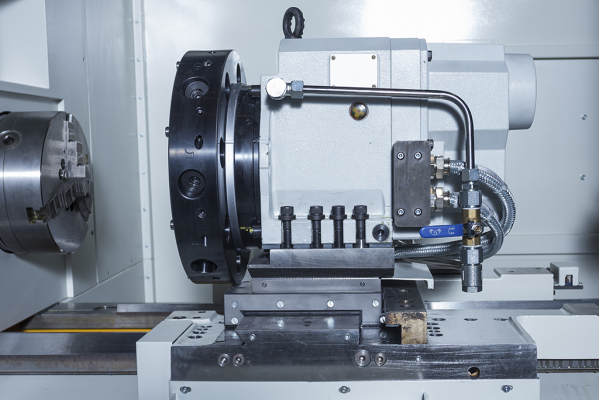

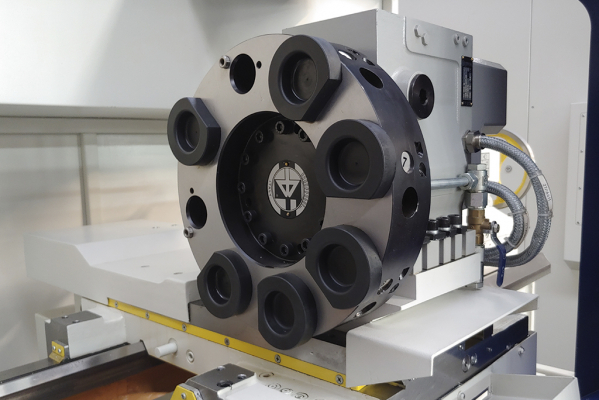

| TOOLHOLDER | ||

|

Number of tools |

8 (4) | |

| Tool section |

25x25 (32x32) |

mm mm |

| Tool change | automatic | |

| TAILSTOCK | ||

| Quill travel | 180 | mm |

|

Quill diameter |

80 |

mm |

| Quill taper | MT5 |

|

| DIMENSIONS AND WEIGHT |

|

|

| Length |

3297 3877 4377 5377 |

mm mm mm mm |

|

Width without panel swivel with panel swivel |

1616 2220 |

mm mm |

| Height | 2170 |

mm |

| Weight |

2800 3200 3500 4000 |

kg kg kg kg |

Completion of the machine

Standard equipment:

- CNC Fanuc 0i-TF

- 3-jaws manual self centering chuck

- 8-position turret with horizontal rotation axis, type VDI40

- Tailstock with dead center and live centers

- Semi-cover machine protection

- Coolant system

- Chip tray

- Toolkit for machine installation

Request

Ask a Question