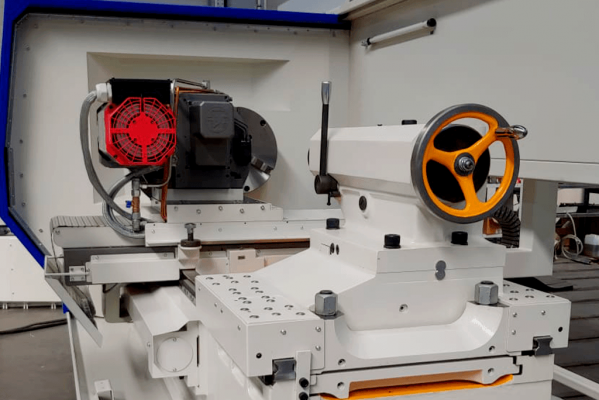

Optimal design solution: rigid solid-cast bed, antibacklash linear slide roller bearing units, five precision angular contact bearings in the spindle unit, feed servo drives and ball screw instead of mechanical kinematic relations – all this ensures accuracy and reliability of the machine.

СА750F2K

Main features

|

Spindle bore diameter |

166 (102*) mm |

|

Max. diameter of the workpiece to be processed over bed |

800 mm |

| Max. diameter of the workpiece to be processed over carriage | 450 mm |

Description of construction

- Advanced cycle CNC control system, provides CNC functions efficiency, facilitates operator`s servicing,

- maintains manual control by means of MPG and intermediate switch.

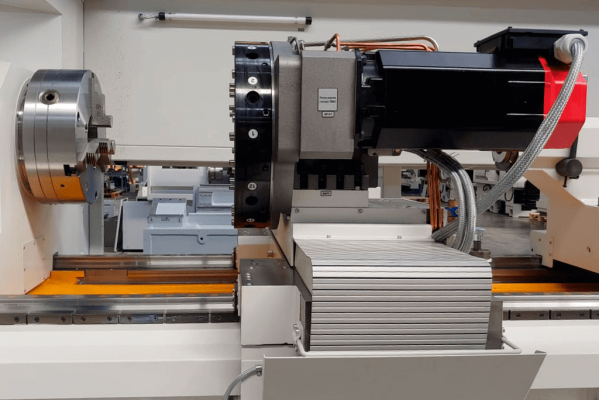

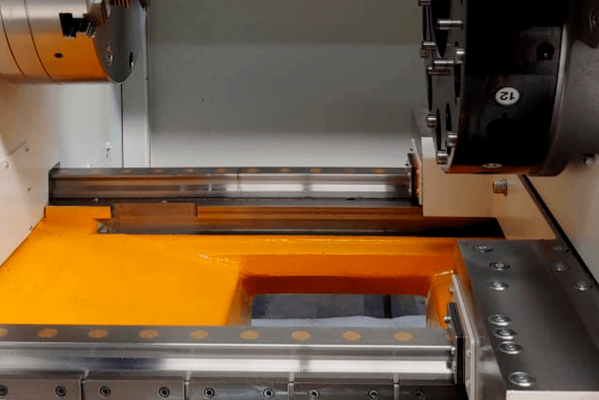

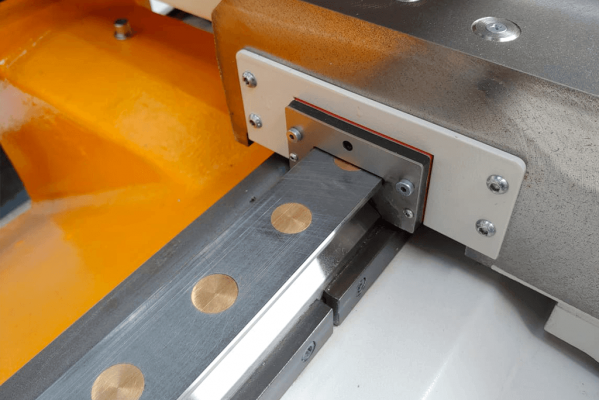

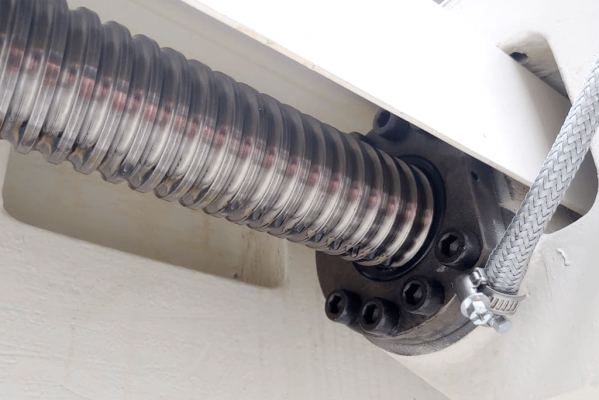

- Optimal design solution: rigid solid-cast bed, antibacklash linear slide roller bearing units, five precision angular contact bearings in the spindle unit, feed servo drives and ball screw instead of mechanical kinematic relations – all this ensures accuracy and reliability of the machine.

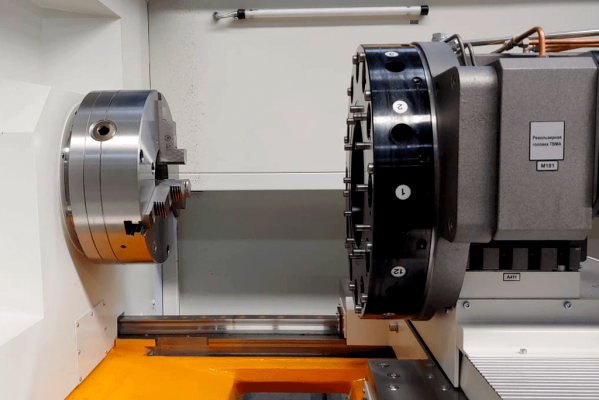

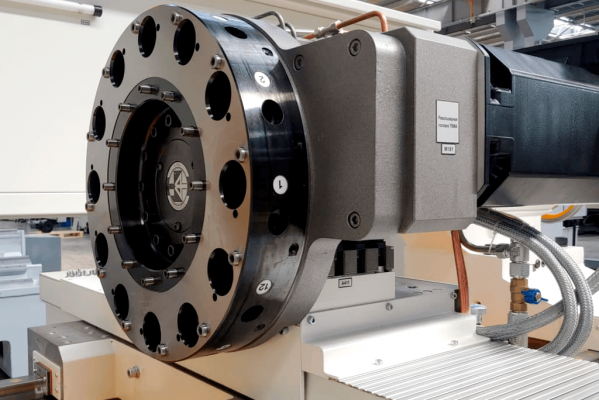

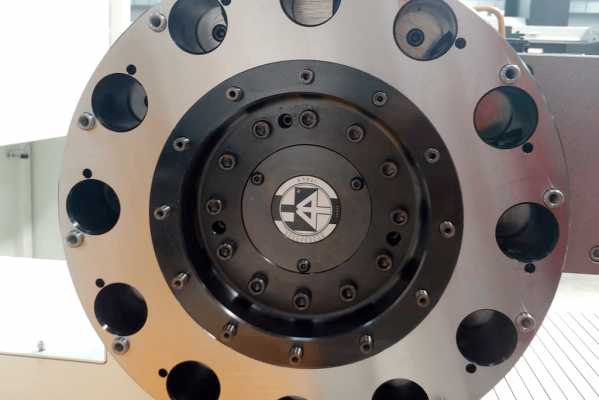

- Turret (up to 8 tools ) with vertical and horizontal rotation axis and with automatic tool change (option) instead of manual tool holder dramatically expands technological capacity of the machine.

Specifications

| CUTTING AREA | ||

|

Max. diameter of the workpiece to be processed over bed |

800 | mm |

|

Max. diameter of the workpiece to be processed over carriage |

450 | mm |

|

Length of processed workpiece |

855 1855 2855 3855 4855 |

mm mm mm mm mm |

|

Max. weight of installed workpiece in chuck in centers |

400 3000 |

kg kg |

| SPINDLE | ||

|

Speed range |

5-2800 (5-2200) |

rpm rpm |

|

Speed adjustment |

stepless, at 2 ranges |

|

| Main motor power/ 30 min | 32,6/40 | kW |

|

Max. torque/ 30 min |

1500/1875 | Nm |

| Chuck diameter |

400 (500, 630) |

mm mm |

| Spindle nose according to DIN55026 | A11 | |

| Spindle bore |

166 (102) |

mm mm |

| FEED | ||

| Cutting feed range | 1-4000 | mm/min |

| Cut thread range | 0,5-150 | rpm |

| X/Z rapid feed |

6000 |

mm/min |

| TOOLHOLDER | ||

|

Number of tools |

4 (12) | |

| Tool section |

32x32 (40x32 32x32 32x25) |

mm mm mm mm |

| Tool change |

manual (automatic) |

|

| TAILSTOCK | ||

| Quill travel | 240 | mm |

|

Quill diameter |

120 |

mm |

| Quill taper | MT6 |

|

| DIMENSIONS AND WEIGHT |

|

|

| Length |

4565 5565 6565 7565 8565 |

mm mm mm mm mm |

|

Width without panel swivel with panel swivel |

2075 2555 |

mm mm |

| Height | 2400 |

mm |

| Weight |

6150 7150 8150 9150 10150 |

kg kg kg kg |

Completion of the machine

Standard equipment:

- Сycle CNC control system Fanuc

- Control panel with touchscreen

- MPG portable

- 3-jaws manual self centering chuck Ø400 mm

- 4-position toolholder of exact positioning (with hirth coupling 32x32)

- Tailstock with dead center and live centers

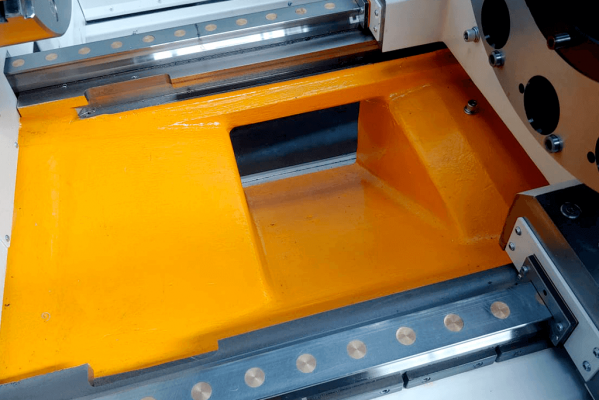

- Semi-cover machine protection

- Work light

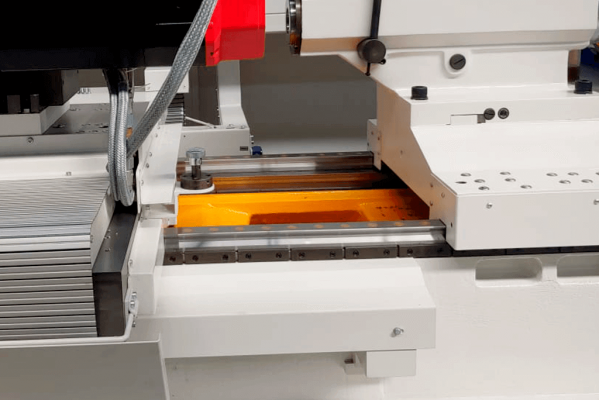

- Coolant system

- Chip tray

- Toolkit for machine installation

Request

Ask a Question