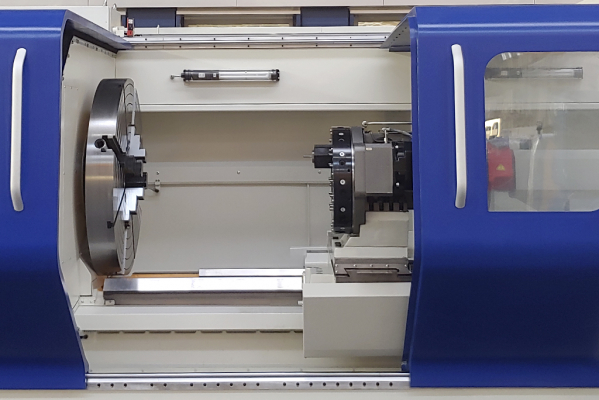

Machines are designed for turning in the chuck and centers of parts with straight, step and curved profile. The range of spindle speed control allows processing of products made of both ferrous and non-ferrous metals and alloy steels.

СА1100F3/F4

Machines are designed for turning in the chuck and centers of parts with straight, step and curved profile. The range of spindle speed control allows processing of products made of both ferrous and non-ferrous metals and alloy steels.

Main features

|

Spindle bore diameter |

180 mm |

|

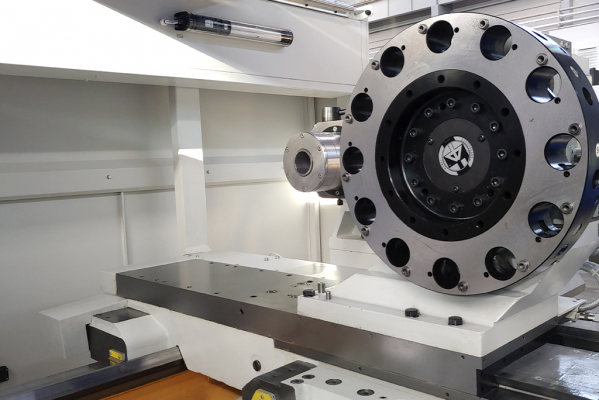

Max. diameter of the workpiece to be installed and processed over bed |

1080 mm |

| Max. diameter of the workpiece to be installed and processed over carriage | 660 mm |

| CUTTING AREA | ||

|

Max. diameter of the workpiece to be installed and processed over bed |

1080 | mm |

| Max. diameter of the workpiece to be installed and processed over carriage | 660 | mm |

| Distance between centers |

1000 2000 3000 5000 7000 8000 12000 |

mm mm mm mm mm mm mm |

| Max. weight of the installed workpiece |

8000 |

kg |

| SPINDLE | ||

| Spindle speed | 5-750 | rpm |

| Speed adjustment |

stepless, at 2 ranges |

|

| Main motor power |

30/37- Fanuc 28/35- Siemens |

kW |

| Max. torque |

4980/6225- Fanuc 5340/6675- Siemens |

Nm |

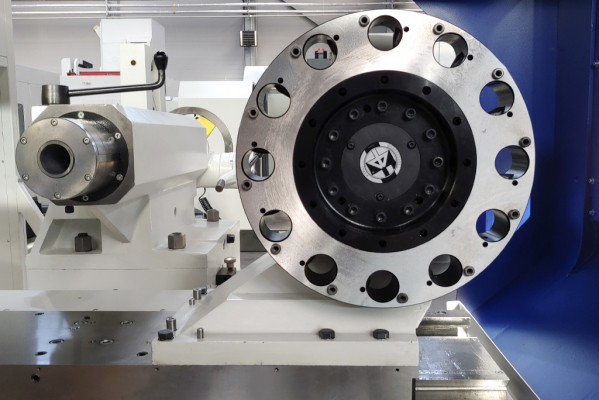

| Chuck diameter |

1000 (500 630 800) |

mm mm mm mm |

| Spindle nose according to DIN55026 | A15 | |

| Spindle bore diameter | 180 | mm |

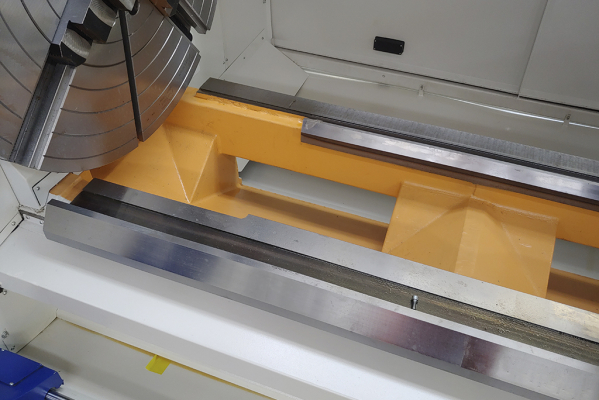

| FEED | ||

| Cut thread stroke limit | 0,1-320 | mm/rev |

| X/Z cutting feed range | 1-4000 | mm/min |

| X/Z rapid feed |

10000 (6000 for DBC=5000 mm) |

mm/min |

| Feed adjustment | stepless | |

|

TURRET |

||

| Number of tools | 4 (12) | |

| Tool section |

40x40 (32x32) |

mm mm |

|

Number of driven tools |

12 | |

| Driven tools power | 7,5 (8,2) | kW |

| Driven tools speed | 5000 | rpm |

| TAILSTOCK | ||

| Quill travel | 275 | mm |

| Quill diameter | 180 | mm |

| Quill taper | MT6 | |

| DIMENSIONS AND WEIGHT | ||

| Length |

5183 6183 7183 ... 16183 |

mm mm mm mm mm |

|

Width without panel swivel with panel swivel |

2655 3317 |

mm mm |

|

Height |

2600 | mm |

| Weight |

10000 11000 12000 ... |

kg kg kg kg |

Request

Ask a Question