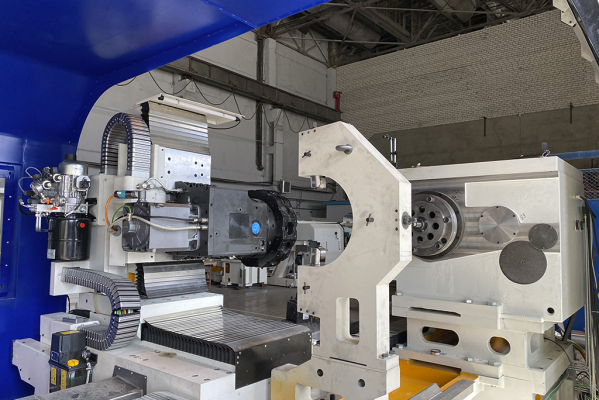

СА1350F3/F4

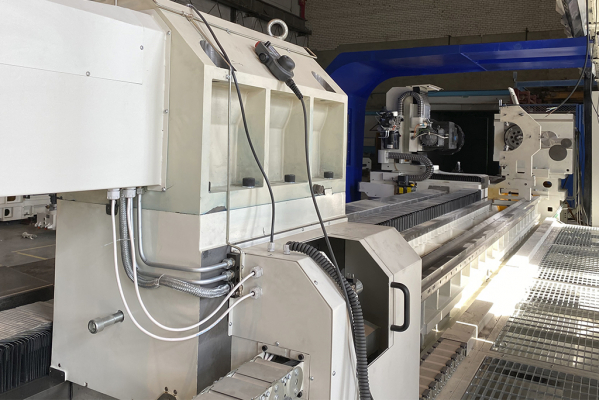

Part processing is carried out along the entire length without reinstalling due to the fact that the carriages have the ability to bypass the rests, go for the headstock and tailstock. The length of the workpiece up to 20 meters, weight up to 25 tons.

Main features

| Spindle bore diameter | 180 mm |

|

Max. diameter of the workpiece to be processed over bed |

1350 mm |

|

Max. diameter of the workpiece to be processed over carriage |

1200 mm |

| Max. weight of the installed workpiece |

12000 (25000) kg |

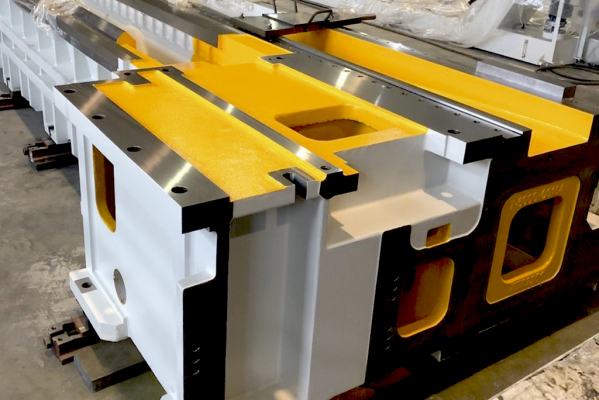

Description of construction

- Provide optimal processing technology for long parts.

- Part processing is carried out along the entire length without reinstalling due to the fact that the carriages have the ability to bypass the rests, go for the headstock and tailstock.

- The length of the workpiece up to 20 meters, weight up to 25 tons.

- It is possible to equip with two carriages and grinding head.

- The positioning accuracy of the axes 20 μm (12 μm optional).

- The carriage moves along the rolling guides, the tailstock is mounted on the sliding guides.

Specifications

| CUTTING AREA | ||

|

Max. diameter of the workpiece to be processed over bed over carriage |

1350 1200 |

mm mm |

|

Max. weight of the installed workpiece |

12000 (25000) |

kg kg |

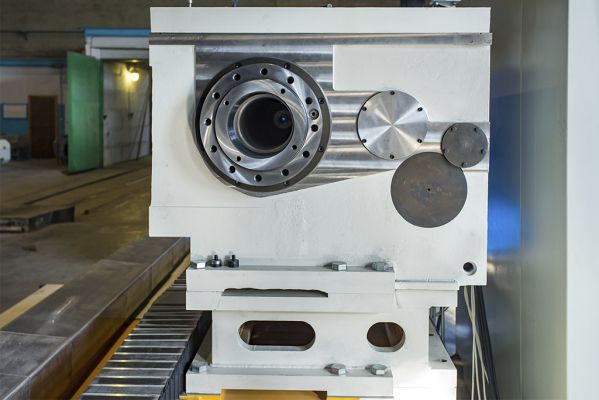

| SPINDLE | ||

| Spindle speed limits | 5-120 | rpm |

| Speed adjustment | stepless | |

| Number of spindle speed ranges | 4 | |

| Main motor power | 30/37 | kW |

| Max. torque | 9160/11450 | Nm |

| Spindle nose according to DIN55026 | A15 | |

| Spindle bore diameter | 180 | mm |

| RAPID FEED | ||

| X axis | 5000 | mm/min |

| Z axis | 5000 | mm/min |

| FEED | ||

| X and Z axes cutting feed range | 0,5-5000 |

mm/min |

| Cut threads stroke limits | 0,1-320 | mm/rev |

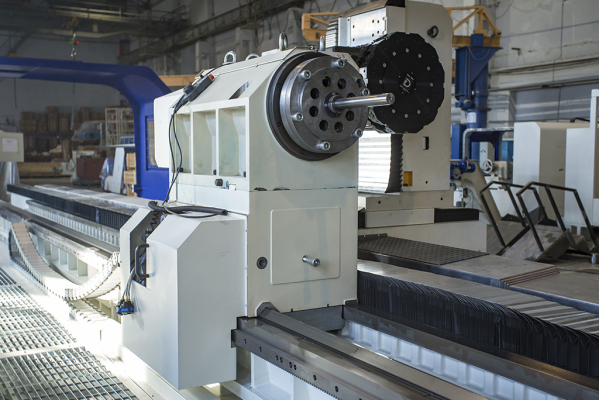

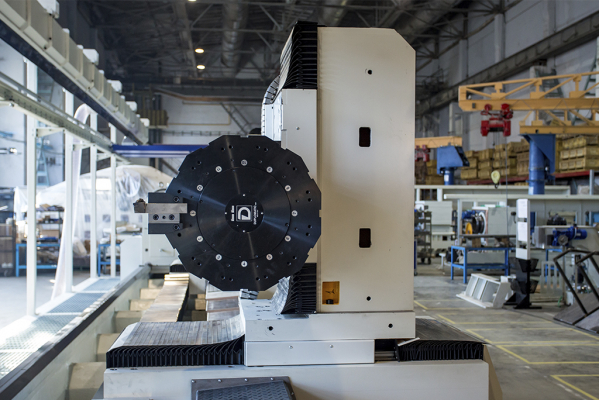

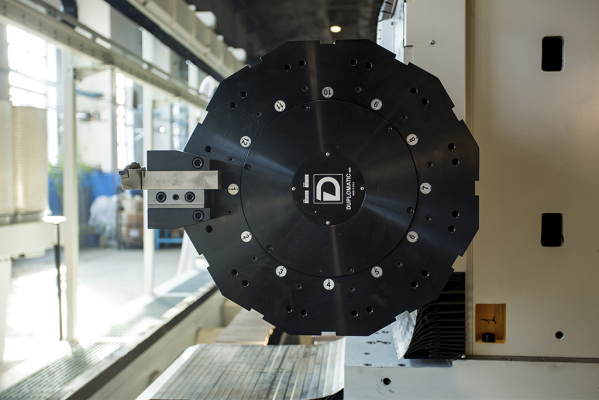

| TURRET | ||

| Number of tools | 4 (12) | |

| Tool section |

40х40 (32х32, VDI50) |

mm mm |

| TURRET WITH DRIVEN TOOL (OPTION) | ||

| Number of driven tools | 12 | |

| Driven tool power | 7,5 | kW |

| Driven tool speed |

2000 (4000) |

rpm rpm |

| TAILSTOCK | ||

| Quill travel | 320 | mm |

| Quill diameter | 280 | mm |

| Quill taper | M90 | |

| DIMENSIONS AND WEIGHT | ||

| Length |

7000 9000 10700 11700 13700 15700 17700 19700 21700 23700 |

mm mm mm mm mm mm mm mm mm mm |

| Width | 3300 | mm |

| Height | 2400 | mm |

| Weight |

13000 15000 17000 18000 20000 22000 24000 26000 28000 30000 |

kg kg kg kg kg kg kg kg kg kg |

Completion of the machine

Standard equipment:

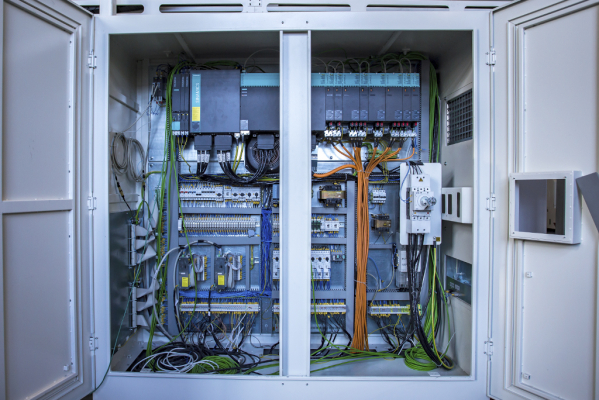

- Fanuc 0i-TF CNC system including all drivers

- MPG portable

- 4-jaw chuck with independent movement of jaws Ø1000 mm

- One carriage

- 4-position turret with vertical axis

- Tailstock with a rotating spindle build into the quill complete with center, quill hydraulic driver and moving electric driver

- Hydraulic station

- Coolant system

- Chip tray

- The protection guarding of the cutting area with one movable gate

- Work light

- Leveling pads

Request

Ask a Question