The "C" axis and the milling function (F4 series) significantly expand the technological capabilities of the machine, allow milling, axial drilling and boring, threading and other operations. A special version of the machine with interchangeable face plates is possible.

ВТ2000F3/F4

Main features

|

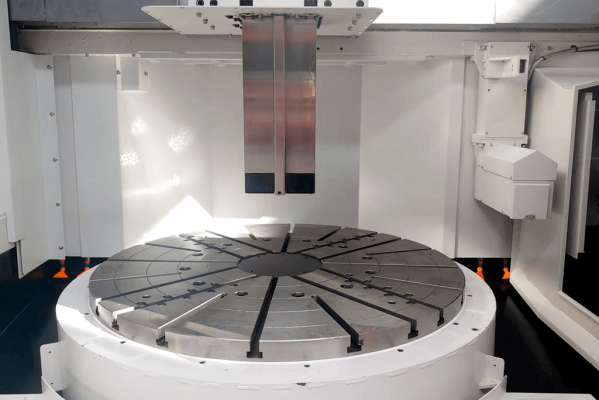

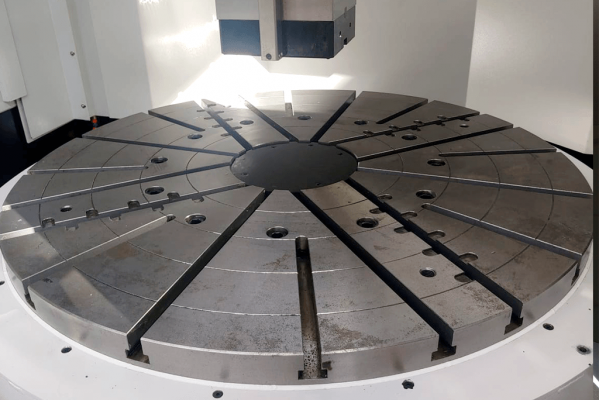

Facing plate diameter |

2000 mm |

|

Max. diameter of the workpiece to be proccesed |

2300 mm |

|

Max. height of the workpiece to be proccesed |

1600 (2000) mm |

Description of construction

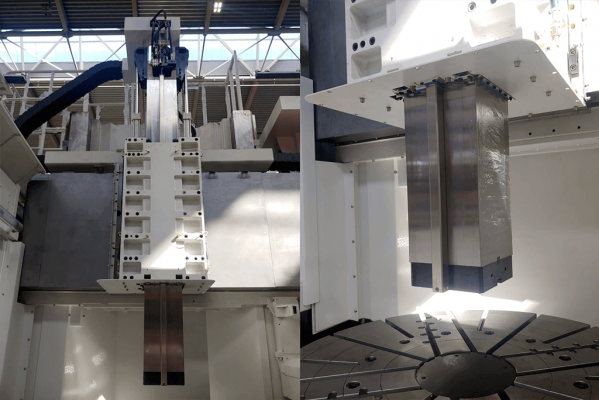

- Solid cast slant-bed of high quality cast iron ensures high rigidity and vibration resistance.

- The balancing system of the machine is built on a nitrogen battery, providing the best anti-vibration characteristics compared to counterbalanced balancing systems.

- High spindle drive power.

- The milling function significantly expand the technological capabilities of the machine.

Specifications

| CUTTING AREA | ||

|

Facing plate diameter |

2000 | mm |

| Max. diameter of the workpiece to be installed | 2500 | mm |

| Max. diameter of the workpiece to be proccesed | 2300 | mm |

| Max. height of the workpiece to be proccesed | 1600 (2000) | mm |

| Max. workpiece weight | 15000 | kg |

| FACING PLATE | ||

| Spindle speed | 2-200 | rpm |

| Torque | 46000 | Nm |

| Main motor power |

60/75 (75/100) |

kW |

| TRAVEL | ||

| Carriage horizontal travel | 2275 | mm |

| Vertical ram travel | 1100 (1500) | mm |

| Cross rail travel | 1150 | mm |

| FEED | ||

| Cutting feed | 0,01-50 | mm/rev |

| X axis rapid feed | 12 | m/min |

| Z axis rapid feed | 10 | m/min |

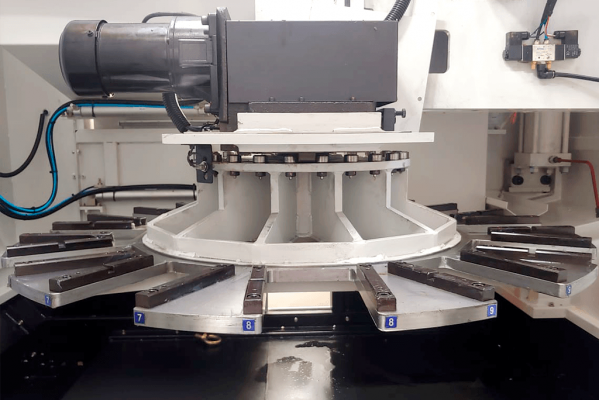

| ATC | ||

| Number of tools | 12 | |

| Tool type | BT50 | |

| Max. tool weight | 50 | kg |

|

MILLING SPINDLE (+ “С” axis) for F4 series |

||

| Spindle speed | 2400 | rpm |

| Milling spindle torque | 730 | Nm |

| Milling spindle motor power | 11/15 (18/22) | kW |

| RAM | ||

| Ram section | 280х280 | mm |

| DIMENSIONS AND WEIGHT | ||

| Length | 5050 | mm |

| Width | 7600 | mm |

| Height | 6700 | mm |

| Weight | 43000 | kg |

Completion of the machine

Standard equipment:

- Fanuc 0i-TD CNC system (or Fanuc 0i-TF)

- ATC for 12 tools

- Chiller for gearbox and facing plate

- 4-jaws facing plate

- BT50 tool shank

- Cross beam lifting and lowering system with hydraulic clamping at 4 points

- Auto lubrication system for guideways

- Chip conveyor with chip tank

- Electronic handwheel

- Protective covers

- Transformer

- Leveling pads

- Tool kit

Request

Ask a Question