HT700F3/F4

Solid cast iron cast iron bed with high damping characteristics. Wide (710 mm) prismatic sliding guides and an increased (50 mm) diameter of ball screws with accuracy class C3 guarantee static and dynamic rigidity over a long service life.

Main features

| Spindle bore diameter | 155 mm |

| Max. diameter of the workpiece to be proceed over bed | 700 mm |

| Max. diameter of the workpiece to be proceed over carriage | 700 kg |

Description of construction

- Solid cast iron cast iron bed with high damping characteristics.

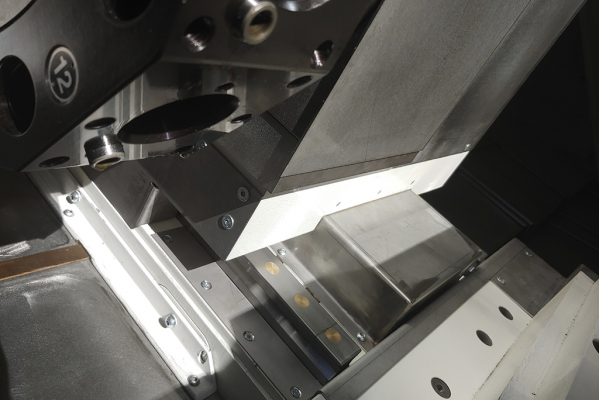

- Wide (710 mm) prismatic sliding guides and an increased (50 mm) diameter of ball screws with accuracy class C3 guarantee static and dynamic rigidity over a long service life.

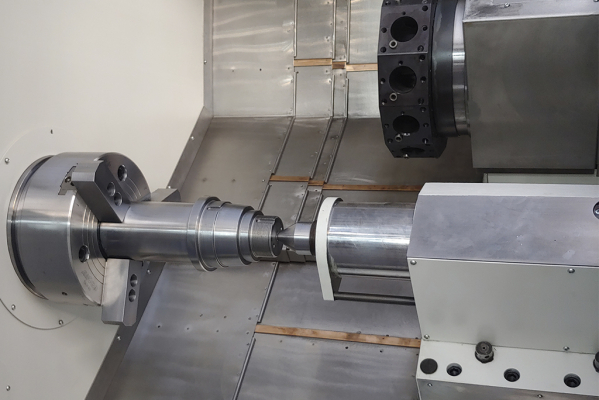

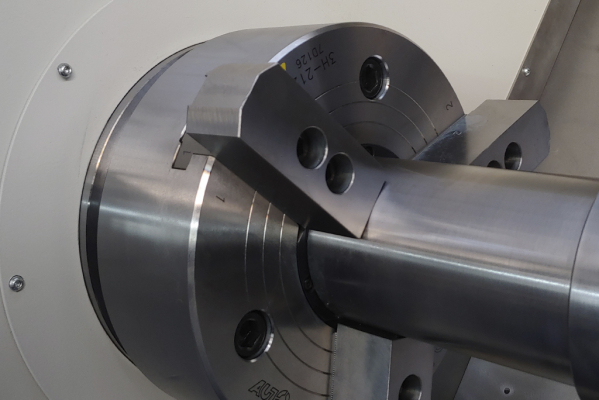

- Reinforced spindle unit with five precision angular contact bearings ensures accuracy and reliability of the machine.

- Spindle speed adjustment (from 0 to 5000 rpm) allows to perfor, machining from both ferrous and non-ferrous metals and from alloyed steels.

- The machine could be equipped with subspindleinstead of tailstock.

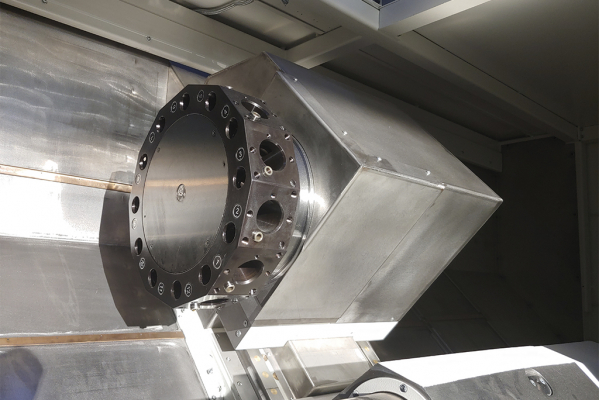

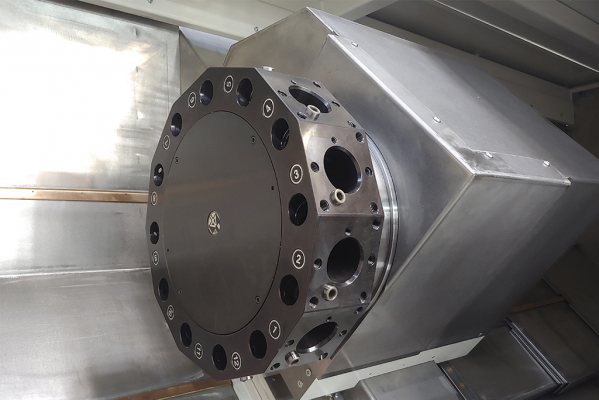

- The 12-position turret VDI60/ВМТ85 with the living tool and the Y axis (option) allows the processing of parts of a complex profile.

- Programmable tailstock with hydraulic quill.

- High (2160 Nm) torque ensures stability under heavy cutting conditions.

- The surfaces of movable units (carriage, tailstock) are scraped and covered with a special anti-friction coating to move with minimal wear and no friction.

- Machining length up to 3800 mm, the weight of the workpiece in the centers – 3000 kg.

Specifications

| CUTTING AREA | ||

| Max. diameter of the workpiece to be installed over bed | 900 | mm |

| Max. diameter of the workpiece to be processed over bed | 700 | mm |

| Max. diameter of the workpiece to be processed over carriage | 700 | mm |

| Length of the workpiece to be processed |

1300 1800 2800 3800 |

mm mm mm mm |

| Max. weight of the workpiece installed in the chuck | 1000 | kg |

| Max. weight of the workpiece installed in the centers | 2000 | kg |

| Max. weight of the workpiece installed in the centers and rest | 3000 | kg |

| SPINDLE | ||

|

Max. spindle speed |

3000 (5000) | rpm |

| Main motor power | 30/37 | kW |

|

Max. torque |

1747/2160 | Nm |

| Spindle speed adjustment |

stepless at 2 ranges |

|

| Spindle taper according to DIN55026 | А2-11 | |

| Chuck diameter |

450 (500, 600) |

mm mm |

| Spindle bore | 155 | mm |

| Bar bore diameter | 117 | mm |

| TRAVEL | ||

|

X axis travel |

385 | mm |

|

Z axis travel |

1500 2000 3000 4000 |

mm mm mm mm |

| W axis travel (tailstock) |

1300 1800 2000 3800 |

mm mm mm mm |

| Y axis travel (option) | ±55 | mm |

| FEED | ||

| X/Z cutting feed | 1-10000 | mm/min |

| X/Z rapid feed | 20000 | mm/min |

|

TURRET |

||

| Number of tools (including driven) | 12 (12) | |

| Tool type | VDI60/BMT85 | |

| Drive power | 3,7 | kW |

| Max. torque | 35 | Nm |

| Tool speed | 4000 | rpm |

| TAILSTOCK | ||

|

Type of tailstock movement |

programmable | |

| Tailstock construction type | with quill hydraulic drive | |

| Quill taper | MT5 | |

| DIMENSIONS AND WEIGHT | ||

| Length |

5600 6500 7200 8200 |

mm mm mm mm |

|

Width |

2500 | mm |

| Height | 2400 | mm |

| Weight |

12000 14000 16000 17000 |

kg kg kg kg |

Completion of the machine

Standard equipment:

- Fanuc 0i-TF

- MPG portable

- Hydraulic 3-jaws self centering chuck

- 12-position turret with driven tool, VDI60

- Tailstock with hydraulic quill, with a rotating spindle built into the quill, with center

- Hydraulic station

- Auto lubrication system for guideways

- Foot pedal to control the chuck and tailstock

- Coolant system with coolant tank

- Full cover protection

- Work light

- Spare parts kit

- Leveling pads

Request

Ask a Question