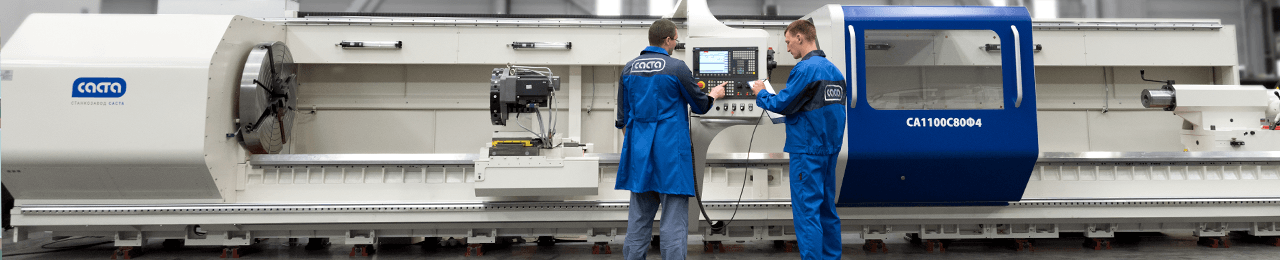

Machine tool factory Sasta is a Russian enterprise with half-century of existence, which preserved and inherited the best traditions of the Soviet machine building industry. Machines produced by Sasta have proved themselves as quality and reliable equipment known through out the world. Equipment made by Sasta is supplied to machine building enterprises in Russia and is exported as well.

Sasta is one of few enterprises who managed to keep production culture, technical potential, engineering and working staff through the tough times.

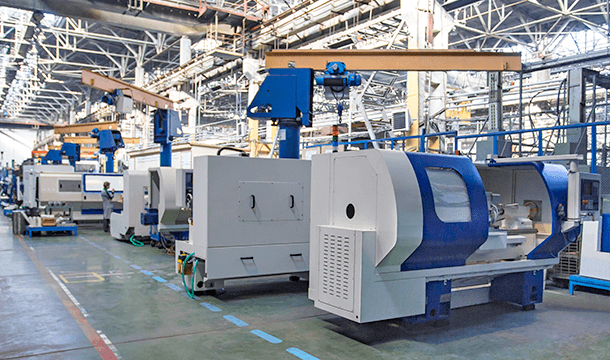

The main activity of the modern "Sasta" is a full cycle of metal cutting machines production:

from design and casting to final assembly.

The Factory has 6 technological areas necessary for full cycle production.

The factory production facilities are more than 75,000 m2.

The technological capabilities of the enterprise allow producing products of any complexity:

• horizontal lathes;

• flat bed lathes;

• turning and milling machining centers;

• lathes;

• slant bed machines;

• pipe-threading machines.

Accuracy and reliability of Sasta products are ensured by a closed production cycle: the most important machine components are produced and processed directly at the factory.

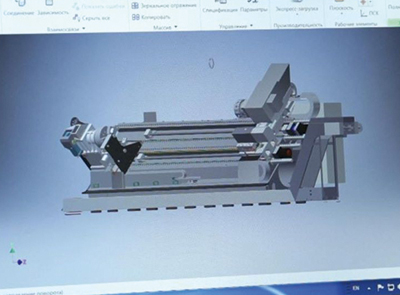

Research and development department

Research and development department has been operating on a base of the machine building factory "Sasta" for more than 40 years. During this time, a product line of reliable and high-quality Russian metal cutting equipment was created, and successfully used at many domestic and foreign factories. Sasta machines operate at enterprises of the defense industry complex, machine building, oil and gas complex and are exported to 39 countries.

All machines of the model range "Sasta" are developed by own R&D department.

R&D department performs a full cycle of design works:

• development of technical specifications;

• development of mechanical components: beds, spindle heads, support groups, etc.;

• development of hydraulic and pneumatic control systems;

• development of cladding and cabinet protection;

• development of electrical equipment for machine tools.

Machines are developed taking into account modern design solutions and components and using advanced technologies well known in the world machine-building construction.

Foundry

One of the most important advantages of "Sasta" is its own foundry, which has technological flexibility, as well as the ability to produce cast iron in single or batch production.

The foundry was opened in 2003. The design capacity is 250 tons of cast iron per month.

The parts of the foundry are equipped with modern melting equipment:

• induction melting units INDUCTOTHERM;

• IMF forming equipment using the third generation high-speed mixers and mechanical regeneration of the molding mixture;

• automated line of moldless molding.

The implemented technology based on cold-hardening mixtures allows obtaining molds of high dimensional accuracy, which makes it possible to produce any castings with minimal allowances for machining.Finished casting has a high surface quality without metallized and chemical fumes.

Industrial laboratory

The laboratory includes the following units:

• spectral laboratory;

• mechanical laboratory;

• metallographic laboratory;

• mixture laboratory;

• chemical laboratory.

The sites are fitted with special equipment which allows carrying out all necessary types of control: from the analysis of incoming mate- rials to the control of melt chemical composition and microstructure of castings.

Qualified personnel performs control of cast- ings at different production stages, including test works and metrological supervision.

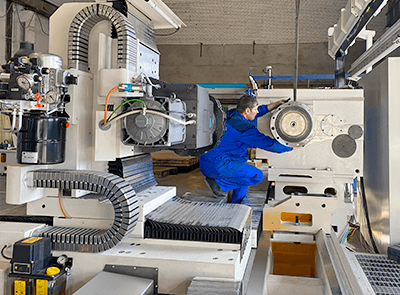

Machining workshop

The machine-building factory "Sasta" performs machining processes of its own casting - complex body part for the metal cutting equipment production.

The factory stock comprises more than 200 machines, including the following unique equipment:

• automatic line Toyoda, consisting of two Toyoda FA800S machining centers, with the possibility of continuous uninterrupted operation for 72 hours without operator’s involvement. The line includes workpiece feeding system consisting of 50 interchangeable pallets and automatic tool changing system for 330 tools;

• 5-axes portal machining center Micromat, designed to handle large parts with a high precision. Precision accuracy is provided by the temperature control system at the main machine components;

• cylindrical grinding machine Studer for spindle units final machining;

• horizontal milling centers with CNC;

• double-column machining centers;

• surface-grinding machining centers;

• planing machines;

• internal grinding equipment;

• gear milling machines and gear grinding machines;

• turning machining centers;

• milling machining centers;

• waterjet and laser machines;

• rolling-and-bending equipment including 4-roll hydraulic bending machine;

• own-produced equipment: turning and turning-milling centers Sasta.

Currently the plant is conducting technical production re-equipment: the production capacity is expanded due to the introduction of modern high-tech equipment, measuring and control devices, which, in its turn, ensures an uninterrupted production cycle and efficiency growth.

Assembling

Assembling areas:

• component assembly;

• electric wiring assembling;

• general machines assembling area;

• coating area;

• resting and after-sales training;

• packing.

Within the assembly cycle Sasta specialists perform function testing of each machine during 96 hours. The factory facilities allow assembling of any equipment including heavy-duty and large-sized machines.